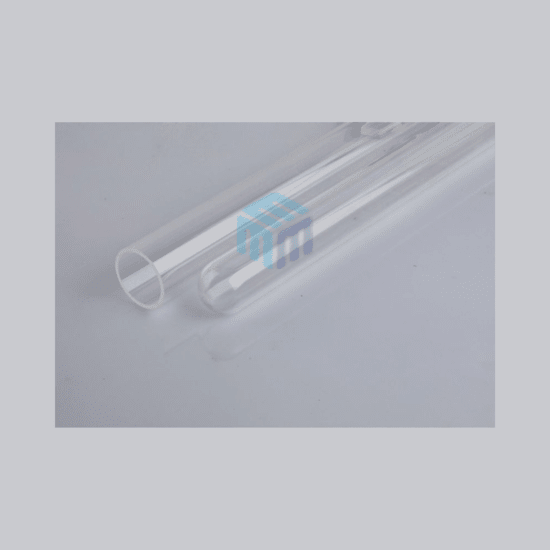

Quartz tubes have become essential components across a wide range of scientific, industrial, and manufacturing applications due to their exceptional thermal stability, chemical resistance, and optical clarity. Whether used in high-temperature furnaces, semiconductor processing, or laboratory experiments, quartz tubes offer unique advantages that make them indispensable in modern technology. In this blog, we’ll explore the key properties that set quartz tubes apart, examine their diverse uses across industries, and provide practical maintenance tips to help ensure their longevity and optimal performance.

Properties of Quartz Tubes:

Quartz tubes offer excellent thermal stability, withstanding temperatures up to 1200°C and sudden temperature changes without cracking. They provide high chemical resistance against most acids and gases, and their exceptional optical clarity makes them ideal for processes requiring UV transmission. Here are the properties of quartz tubes:

High-Temperature Resistance: Quartz tubes can withstand high temperatures, typically up to around 1200°C (2192°F) for continuous use and even higher for short-term applications. This makes them suitable for processes involving heating, annealing, and thermal treatment.

Thermal Stability: Quartz has excellent thermal stability, meaning quartz tubes can maintain their structural integrity and dimensional stability at high temperatures without softening or deformation.

Chemical Inertness: Quartz is highly resistant to most acids, alkalis, and corrosive chemicals, making quartz tubes suitable for handling a wide range of chemicals and reactive substances without degradation.

Transparency: Quartz tubes are transparent to ultraviolet (UV) and visible light, allowing for optical monitoring and analysis in UV spectroscopy, photolithography, and other optical applications.

Electrical Insulation: Quartz is an excellent electrical insulator, making quartz tubes suitable for electrical insulation in high-voltage equipment, electrical furnaces, and semiconductor processing.

Low Thermal Expansion: Quartz has a low coefficient of thermal expansion, meaning quartz tubes experience minimal dimensional changes with temperature fluctuations. This property helps prevent thermal stress-induced cracking.

Uses of Quartz Tubes:

Quartz tubes are widely used in high-temperature furnaces, laboratory heating systems, and semiconductor manufacturing. They play a key role in crystal growth, chemical vapor deposition (CVD), and thermal processing due to their purity, transparency, and ability to withstand harsh chemical environments.

Heating and Annealing: Quartz tubes are commonly used as heating elements or containment vessels in high-temperature processes such as annealing, brazing, melting, and soldering of metals, ceramics, and semiconductor materials.

Chemical Processing: Quartz tubes find applications in the chemical industry for chemical reactions, distillation, evaporation, and sample containment. They are resistant to corrosive chemicals and high temperatures, making them ideal for harsh chemical environments.

Laboratory Equipment: Quartz tubes are used in laboratories for various applications, including quartzware for chemical analysis, sample digestion, atomic absorption spectroscopy (AAS), and other analytical techniques requiring high-purity containers.

UV Sterilization: Quartz tubes are used in UV sterilization systems for water purification, air sterilization, and surface disinfection. The transparency of quartz to UV light allows for effective germicidal action.

Optical and Semiconductor Applications: Quartz tubes are used in optical instruments, laser systems, semiconductor manufacturing, and photolithography processes due to their optical transparency, thermal stability, and chemical inertness.

Maintenance Tips for Quartz Tubes:

Handle quartz tubes carefully to avoid mechanical shock and scratching. Always clean using mild detergents or approved solvents to remove residues without damaging the surface. Avoid rapid heating or cooling to prevent thermal stress. Regular inspection for cracks or contamination ensures safe and efficient operation.

Cleaning: Clean quartz tubes regularly to remove residues, deposits, and contaminants that can affect their performance. Use mild cleaning agents and avoid abrasive materials that could scratch or damage the quartz surface.

Avoid Thermal Shock: Gradually heat and cool quartz tubes to avoid thermal shock, which can cause cracking. Use controlled heating and cooling rates to minimize stress on the tubes.

Handle with Care: Handle quartz tubes carefully to prevent mechanical damage. Avoid dropping or impacting the tubes, especially at elevated temperatures.

Inspect for Damage: Periodically inspect quartz tubes for signs of wear, damage, or thermal stress. Replace any damaged tubes promptly to maintain performance and safety.

Storage: Store quartz tubes in a clean, dry environment to prevent contamination and moisture absorption. Use protective packaging or racks to avoid physical damage during storage.

By understanding the properties, uses, and maintenance tips for quartz tubes, you can ensure their optimal performance and longevity in various applications requiring high-temperature resistance, chemical inertness, and optical transparency.

Conclusion:

Quartz tubes offer an unmatched combination of thermal stability, chemical resistance, and optical clarity, making them indispensable across various high-tech industries and laboratory applications. By understanding their key properties, diverse uses, and following proper maintenance practices, users can maximize the performance and lifespan of quartz tubes while ensuring safety and efficiency in critical processes. As technology continues to advance, the demand for high-quality quartz tubes will only grow, further highlighting their importance in modern material processing and scientific research.

M-Kube Enterprise is an Australian company catering customized laboratory products, laboratory consumables, and laboratory solutions in Australia, India, the USA, New Zealand, Singapore, Malaysia, South Korea, Dubai, the Philippines, Indonesia, and Vietnam.