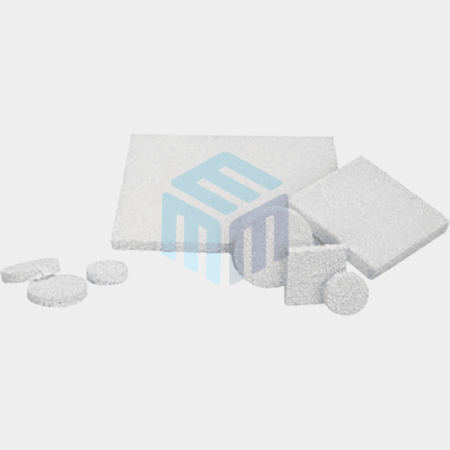

Alumina Discs/ Alumina Plates

Inquiry NowProduct Description

Alumina discs/Alumina plates, also known as alumina ceramic discs, are specialized circular or disc-shaped components made from alumina or aluminum oxide (Al2O3). Alumina is a versatile ceramic material known for its excellent mechanical, electrical, and thermal properties. Alumina discs find a wide range of applications in various industries due to their high-temperature resistance, electrical insulation, and wear resistance. Here are key features and applications of alumina discs:

Key Features:

- High-Temperature Resistance: Alumina discs can withstand high temperatures, making them suitable for applications involving heat and thermal stress.

- Mechanical Strength: They have good mechanical strength, which enables them to withstand mechanical loads and impacts.

- Electrical Insulation: Alumina is an electrical insulator, making alumina discs ideal for electrical and electronic applications.

- Chemical Inertness: Alumina is chemically inert and resistant to most chemicals, acids, and alkalis, ensuring corrosion resistance.

- Wear Resistance: Alumina discs offer excellent wear resistance, making them suitable for applications where wear and abrasion are common.

Applications:

- Electrical Insulators: Alumina discs/Alumina plates are used in electrical and electronic equipment to provide insulation and support for electrical components, such as transistors, resistors, and capacitors.

- Thermal Insulators: They find application as thermal insulators in high-temperature environments, such as in kilns, ovens, and furnaces, where they help maintain temperature stability.

- Wear Components: Alumina discs are used as wear components in mechanical systems, such as in pumps, seals, and bearings, to reduce wear and extend the lifespan of components.

- Laboratory Equipment: Alumina discs are used in laboratory equipment, such as crucibles, trays, and sample holders for high-temperature sample preparation and analysis.

- Cutting and Grinding Tools: They are used in cutting and grinding tools, such as alumina abrasive discs, for precision machining applications.

- Alumina Substrates: Alumina discs/Alumina plates serve as substrates for electronic circuits and sensors, especially in the semiconductor and sensor manufacturing industries.

- Chemical Processing: They are employed in chemical reactors and vessels to resist the corrosive effects of chemicals and maintain structural integrity at high temperatures.

- Medical and Dental Devices: Alumina discs are used in medical and dental devices for their biocompatibility and resistance to wear and corrosion.

- Optical Components: Alumina discs find application in optical systems as windows, substrates, and lens components.

- Ceramic and Advanced Materials Production: They are used in the production of ceramics and advanced materials, including advanced composites and superconductors.

Alumina discs/Alumina plates come in various sizes, thicknesses, and surface finishes to meet specific application requirements. They can be customized for specific applications, such as dimensions, tolerances, and surface treatments. Proper selection and handling are essential to ensure the optimal performance of alumina discs in various industrial and technological applications.

M-Kube Enterprise is an Australian company catering customized laboratory products, laboratory consumables and laboratory solutions in Australia, Dubai, India, Indonesia, Malaysia, New Zealand, Philippines, Singapore, South Korea, USA, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us on info@mkube.com.au or call us on +61478594746 to discuss your projects.