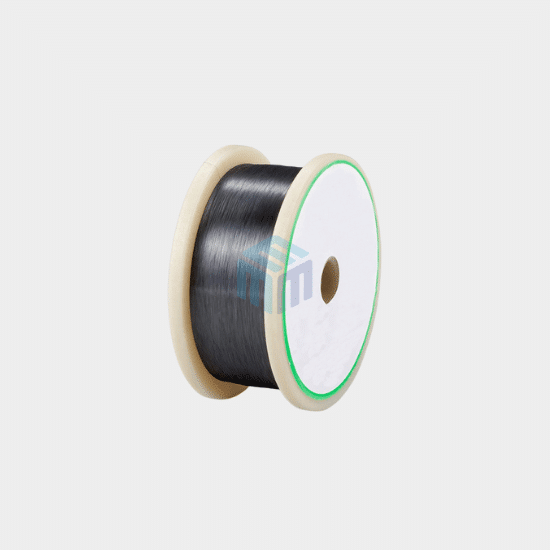

Tungsten Wires

Inquiry Now| Sr No | Product Code | Description | MOQ | Sell Price (in AUD) |

|---|---|---|---|---|

| 1 | Tu-WB-000.5mm-0050m-00001 | 99.5% Tungsten Black Wires Dia 0.5 mm, L 50 m | 25 | $7.45 |

| 2 | Tu-WB-000.8mm-0025m-00002 | 99.5% Tungsten Black Wires Dia 0.8 mm, L 25 m | 25 | $16.7 |

| 3 | Tu-WB-001.0mm-0025m-00003 | 99.5% Tungsten Black Wires Dia 1 mm, L 25 m | 25 | $20 |

| 4 | Tu-WB-080.0um-1000m-00004-S | 99.5% Tungsten Black Wires Dia 80 um, L 1000 m | 50 | $16 |

| 5 | CUSTOM REQUIREMENT | We can customize your requirements as per your needs Email [email protected] or Call on +61478594746 | CONTACT US |

Product Description

General information

Tungsten wires’ production process includes sintering, drawing, pressing swaging, and annealing at high temperatures. Despite going through a high-pressure process, tungsten wire retains the properties of the metal. Properties include high melting and boiling point, low thermal expansion coefficient, and low vapour pressure.

Tungsten wires hold beneficial electrical and thermal conductivity qualities, which make it valuable for lighting, thermocouple and electronic device applications. Most tungsten wires are doped, a process that gives the wires a non-sag ability. Tungsten wires are ductile and can be used in high temperatures as well. It was primarily used in incandescent lights but now its applications have expanded, including industrial oven and vacuum metalizing. Undoped tungsten wires are available as well but they require to be of the highest purity, 99.9% pure, to be used for various purposes. The strength of the wires is based on their diameters which can be customised as per the requirements.

M-Kube Enterprise is an Australian company catering customized laboratory products, laboratory consumables, and laboratory solutions in Australia, Dubai, India, Indonesia, Malaysia, New Zealand, the Philippines, Singapore, South Korea, the USA, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us on [email protected] or call us on +61478594746 to discuss your projects.

We also provide Tungsten Crucibles, Tungsten Boats, Tungsten Electrodes, Tungsten Mandrels, Tungsten Foils, Tungsten Sheets and Plates, Tungsten Tubes, Tungsten Rods and Bars, and Tungsten substrates.

Key properties

Tungsten is a refractory material that can withstand high temperatures. Significant features include –

- High melting point (3410 °C)

- Low thermal expansion

- High electrical resistance

- Low vapour pressure

- High density

- Resistance to oxidation and creep

- Extreme hardness

- High tensile strength

Application

Due to tungsten wires’ strength, excellent resistance to high temperature and other beneficial qualities, it is used: –

- For automobile turn signals

- For thermocouples

- For borescopes

- To manufacture electron emitting devices

- For lighting components

- To produce heating parts for high-temperature furnaces

- To produce electronic devices such as integrated circuits, for semiconductor silicon pulling

- To produce helical springs for devices that are baked at high temperatures

- In different types of probes, such as cantilever semiconductor test probes

- For medical diagnostics and treatment such as neural probes

- To produce electrodes for welding