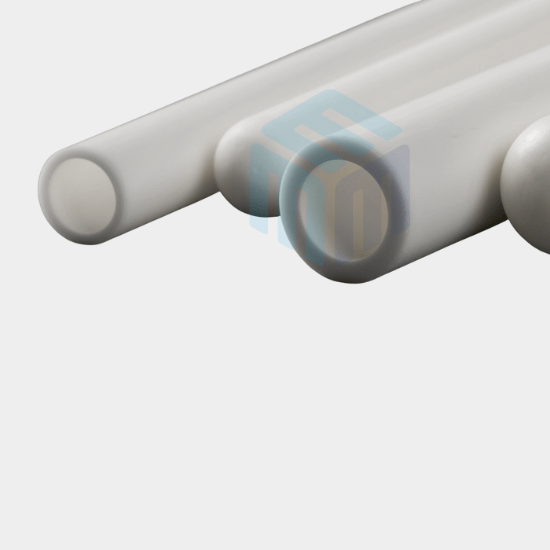

Zirconia Tubes, Zirconia Pipes and Zirconia Rods

Inquiry NowProduct Description

General Description:

Material: Zirconia ceramic components can be used for extreme service applications owing to its excellent erosion, corrosion, abrasion and temperature resistance at temperatures well above the melting point of alumina. Zirconia tubes and rods are ceramic products primarily composed of zirconia also known as zirconium dioxide (ZrO2), which can exist in different crystal phases, such as monoclinic, tetragonal, and cubic. The phase composition can be modified through stabilization techniques to achieve desired properties.

Some of the different Zirconia grades based on their stabilization techniques are as follows:

- Mg-PSZ (Magnesia – Partially stabilized Zirconia) – Highest toughness grades.

Used in severe-service applications. Characteristics like high corrosion resistance, durability, and toughness make it an ideal choice for machinery parts and valves in severe applications. 1Mg-PSZ is a partially stabilized zirconia material that contains around 1% to 2% magnesium oxide (MgO) as a stabilizer. It exhibits good thermal stability and mechanical strength at high temperatures. Maximum Temperature: Approximately 1,200°C to 1,400°C (2,192°F to 2,552°F)

- Zirconia MS – Highest Strength grade

Characteristics like high wear and corrosion solutions make it an ideal choice for material handling industries. Zirconia MS refers to zirconia stabilized primarily in the monoclinic phase. Maximum Temperature: Approximately 1,500°C to 1,700°C (2,732°F to 3,092°F)

- Zirconia TS – High Thermal Shock grade

Characteristics like high thermal shock resistance make it an ideal choice for applications like non-ferrous metal extrusion. Maximum Temperature: Approximately 1,200°C to 1,500°C (2,192°F to 2,732°F). Zirconia TS is zirconia primarily stabilized in the tetragonal phase. It possesses high fracture toughness and can tolerate elevated temperatures.

- Y-TZP (Yttria – Tetragonal zirconia polycrystal) – Grade with Maximum Hardness and strength along with a finer grain structure.

(YTZP) components are very strong and are used in extreme machinery and mechanical applications that require excellent corrosion and insulative properties, fatigue resistance and impact loading excellence. Y-TZP is a widely used zirconia material with yttria (Y2O3) as the stabilizing agent. Maximum Temperature: Approximately 1,500°C to 1,700°C (2,732°F to 3,092°F)

- Y-FSZ (Yttria – Fully stabilized zirconia) – A Grade for strong thermal shock resistance, fracture toughness, superior corrosion resistance, high oxygen diffusivity/ electrical conductivity.

Maximum Temperature: Approximately 1,500°C to 1,700°C (2,732°F to 3,092°F). Y-FSZ is a fully stabilized zirconia material with yttria as the stabilizer. It exhibits improved thermal stability and excellent resistance to high-temperature environments

Please note that the temperature ranges provided are approximate and can vary depending on the specific composition, manufacturing processes, and application requirements. It’s always recommended to consult the manufacturer or technical specifications for precise temperature limits of zirconia tubes and rods.

Top of Form

Manufacturing Process: Zirconia tubes and rods are typically manufactured through methods like extrusion, isostatic pressing, or slip casting.

- Extrusion: In this process, zirconia powder mixed with binders is forced through a die to form the desired tube or rod shape. The extruded structure is then heated to remove the binders and sintered to achieve the final zirconia product.

- Isostatic pressing: Isostatic pressing involves subjecting zirconia powder to high pressure in a flexible mold using fluids. This compacts the powder into the desired shape, which is then sintered to obtain a dense zirconia tube or rod.

- Slip casting: In slip casting, a slurry of zirconia powder in a liquid binder is poured into a mold. The liquid is gradually absorbed by the mold, leaving behind a solid zirconia structure. The cast structure is then sintered to achieve the final product.

Dimensions: Zirconia tubes are hollow cylindrical structures with varying inner and outer diameters, wall thicknesses, and lengths. Zirconia rods, on the other hand, are solid cylindrical structures with uniform diameters and lengths. The dimensions of zirconia tubes and rods can be customized to meet specific application requirements.

Additional features: Zirconia tubes and rods can be customized with additional features like flanges, grooves, or threads to facilitate connections and installations.

It’s important to note that the specific properties and dimensions of zirconia tubes and rods can vary based on the manufacturer and the intended application. Therefore, it’s advisable to consult the M-Kube team for detailed specifications and recommendations based on your specific needs.

M-Kube Enterprise is an Australian company catering customized laboratory products, laboratory consumables, and laboratory solutions in Australia, Dubai, India, Indonesia, Malaysia, New Zealand, the Philippines, Singapore, South Korea, the USA, and Vietnam. As a leading provider of scientific laboratory consumables, we excel in delivering a wide range of high-purity zirconia ceramics. Our offerings include zirconia foam filter, zirconia tubes and zirconia rods, all thoughtfully designed in various dimensions (diameter, thickness, and length) to meet the diverse needs of chemistry and science laboratories. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us on [email protected] or call us on +61 478901616 to discuss your projects.

Properties: Zirconia tubes and rods possess several desirable properties, including:

- High mechanical strength: Zirconia exhibits high flexural strength and fracture toughness, making it resistant to mechanical stress and wear.

- Low thermal conductivity: Zirconia has low thermal conductivity, which can be advantageous in applications requiring thermal insulation.

- Excellent chemical resistance: Zirconia is chemically inert and resistant to corrosion, making it suitable for use in harsh chemical environments.

- High-temperature stability: Zirconia can withstand high temperatures without significant degradation or softening.

- Electrical insulation: Zirconia is an electrical insulator, making it suitable for electrical applications.

- Biocompatibility: Zirconia is biocompatible and finds applications in dental and medical implants.

Applications: Zirconia tubes and rods have a wide range of applications across different industries, including:

- Dental and medical: Zirconia tubes and rods are used in dental prosthetics, orthopaedic implants, and medical devices due to their biocompatibility and strength.

- Aerospace and automotive: Zirconia components find applications in aerospace and automotive industries for their high-temperature stability, wear resistance, and lightweight properties.

- Chemical processing: Zirconia tubes and rods are employed in chemical reactors, pumps, and valves, thermocouple protection tubes, furnace muffles, for their chemical resistance and stability.

- Insulation and heat management: Zirconia tubes are used in insulation systems and thermal barriers to provide heat resistance and thermal insulation.

- Wear-resistant components: Zirconia rods find applications as wear-resistant components in industries such as mining, oil and gas, and material handling.

- Electrical insulation: Zirconia tubes and rods serve as electrical insulators in various high-voltage applications.

- Oxygen Sensors: Zirconia also exhibits a unique ability to allow oxygen ions to diffuse through its crystal structure, above 600ºC. Due to this property, Zirconia ceramic components can be used in making oxygen sensors.