Alumina tubes are widely used in high-temperature applications due to their excellent thermal stability and corrosion resistance. Whether you’re operating a research lab or an industrial furnace, understanding how to use these ceramic components effectively ensures both safety and durability. In this guide, we’ll explore how to maximise the life of alumina furnace tubes, the best practices for their usage, and how to source the right alumina tube suppliers in Australia.

Understanding Alumina Tubes and Their Properties

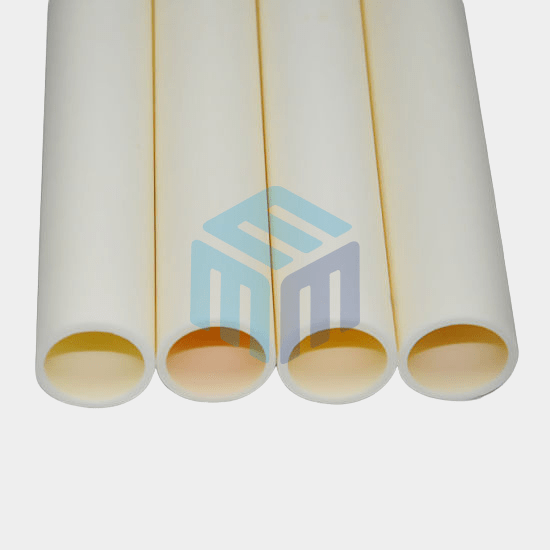

Alumina (Al₂O₃) is a ceramic material prized for its strength, thermal resistance, and insulation properties. Alumina tubes are commonly used in scientific and industrial furnaces due to their:

- High-temperature resistance up to 1800°C

- Excellent electrical insulation

- Resistance to corrosion and chemical attack

- Mechanical strength at elevated temperatures

Alumina tubes are available in various dimensions, with alumina tubes sizes ranging from a few millimetres in diameter for lab-scale use to several centimetres for industrial-scale operations.

When choosing an alumina tube for furnace applications, it’s crucial to match the material’s purity and grain size with your temperature and chemical exposure requirements.

Proper Handling and Storage of Alumina Tubes

Alumina tubes are brittle and can easily crack if mishandled or dropped. It is important to handle them with care and avoid any sudden impacts or jolts. During storage, they should be kept in a dry and clean environment to prevent any contamination or damage.

Preheating

Alumina tubes should be preheated gradually to avoid thermal shock. Rapid temperature changes can cause cracking or even complete failure of the tube. It is recommended to heat the tube slowly at a rate of 100°C per hour until it reaches the desired temperature.

Cleaning

Before using alumina tubes at high temperatures, it is important to clean them thoroughly to remove any impurities or residues. Any foreign material on the surface of the tube can cause contamination or blockages during use. A combination of solvents, detergents, and/or acid solutions can be used to clean the tubes. However, it is important to note that the cleaning process should not damage the tube.

Avoid thermal cycling

Repeated thermal cycling can cause stress on the alumina tube and lead to cracking or even complete failure. To avoid this, it is recommended to use the alumina tube at a steady temperature without any sudden changes.

Proper support and placement

When using alumina tubes at high temperatures, it is important to ensure proper support and placement to prevent any bending or warping. The tube should be placed on a stable and level surface, and any clamps or supports used should be made of materials that can withstand high temperatures.

Cooling

After use, it is important to cool the alumina tube slowly to avoid thermal shock. Rapid cooling can cause cracking or even complete failure of the tube. It is recommended to allow the tube to cool gradually at a rate of 100°C per hour until it reaches room temperature.

In conclusion, alumina tubes are an excellent choice for high-temperature applications due to their exceptional thermal and chemical properties. Proper handling, preheating, cleaning, avoiding thermal cycling, proper support and placement, and cooling are essential to ensure optimal performance and longevity of the tube. By following these guidelines, you can ensure the safe and effective use of alumina tubes in your high-temperature.

Best Practices for Using Alumina Tubes at High Temperatures

Proper handling and operation significantly influence the performance and lifespan of ceramic tubes for furnaces. Follow these guidelines to avoid premature failure:

- Preheating: Avoid thermal shock by gradually heating the tube. Use a stepped ramp-up in temperature.

- Avoid Rapid Cooling: Let the alumina tube cool slowly in the furnace after high-temperature cycles.

- Proper Support: Mount tubes with adequate support to prevent bending or sagging at high temperatures.

- Clean Interior Use: Only introduce compatible materials inside the tube that won’t chemically react with alumina.

- Use in Clean Atmosphere: Avoid excessive moisture or contaminated atmospheres to prevent surface degradation.

Following these practices will ensure your alumina furnace tubes remain structurally sound and thermally efficient over extended use.

Common Applications of Alumina Furnace Tubes

Alumina tubes play a vital role across various high-temperature applications in Australian industries:

- Laboratory Furnaces: As sample holders or reactors in material research.

- Thermocouple Protection: Encasing temperature sensors in extreme conditions.

- Powder Metallurgy: Acting as a barrier between furnace gases and materials.

- Semiconductor Processing: Withstanding reactive atmospheres in controlled environments.

- Ceramic Sintering: Serving as support tubes in kilns or horizontal tube furnaces.

Whether you’re sourcing ceramic tubes for furnaces for academic labs or industrial manufacturing, choosing the right size and specification is critical.

Choosing Trusted Alumina Tube Suppliers

Finding dependable alumina tube suppliers in Australia is essential to ensure quality, consistency, and supply reliability. When evaluating a supplier, consider the following:

- Product Range: Do they offer a wide variety of alumina tubes sizes for different applications?

- Material Purity: High-purity alumina (≥99.8%) is ideal for high-temp applications.

- Customisation Options: Can they fabricate custom lengths, diameters, or closed-end tubes?

- Technical Support: Do they offer consultation or guidance on furnace compatibility?

At M-Kube Enterprise, we supply premium alumina furnace tubes backed by reliable customer service, fast delivery across Australia, and in-depth product expertise.

Conclusion

Alumina tubes are indispensable in high-temperature processes across research, manufacturing, and analytical laboratories. By understanding their properties, adhering to usage best practices, and sourcing from trusted alumina tube suppliers, users can achieve exceptional performance and long service life.

Looking for high-quality alumina tube for furnace use in Australia?

📞 Call us at +61478594746

📧 Email: info@mkube.com.au

🌐 Explore more at www.mkube.com.au