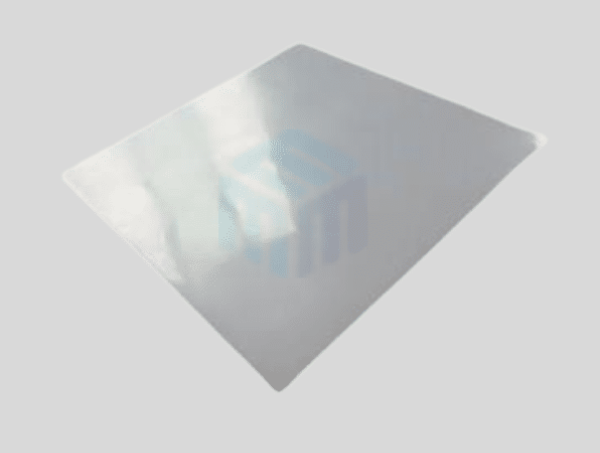

Zirconia (ZrO₂) polished sheets are high-performance ceramic substrates known for their exceptional strength, chemical resistance, and refined surface finish. These advanced materials are used across diverse industries—from biomedical devices to high-temperature furnaces—where precision, durability, and performance are non-negotiable.

In this guide, we’ll explore what zirconia polished sheets are, how they’re manufactured, their key properties, and where they’re most commonly applied.

What Is a Zirconia Polished Sheet?

Zirconia polished sheets are flat ceramic plates made from stabilized zirconium dioxide. These sheets are mechanically polished to achieve a high-gloss, low-roughness surface. Due to zirconia’s superior toughness and hardness, these sheets are ideal for demanding applications that require wear resistance, biocompatibility, and aesthetic appeal.

At M-Kube, we supply zirconia components, crucibles, and other analytical ceramics for high-performance laboratory and industrial use.

Manufacturing Process of Zirconia Polished Sheets

The production of zirconia polished sheets involves several precision-controlled steps to ensure performance and consistency:

- Powder Preparation & Stabilization

High-purity zirconium dioxide is blended with stabilizers (such as yttria) to improve thermal and structural stability.

- Forming

The ceramic powder is compacted into sheet forms using dry pressing or tape casting, ensuring uniform thickness and density.

- Sintering

Sheets are sintered at temperatures up to 1500°C to achieve full density and hardness while minimizing porosity.

- Polishing

Advanced mechanical polishing techniques bring surface roughness down to Ra < 0.05 µm, creating a mirror-like finish suitable for optical and electronic uses.

Properties & Applications of Zirconia Polished Sheets

Key Properties of Zirconia Polished Sheets:

- Exceptional Hardness: Zirconia is harder than alumina, making it more resistant to cracking and wear.

- High Flexural Strength: Ideal for structural components under stress.

- Thermal Stability: Operates reliably at elevated temperatures (~1000°C).

- Chemical Inertness: Resists corrosion from acids, alkalis, and organic solvents.

- Biocompatibility: Safe for use in biomedical devices and implants.

- Low Surface Roughness: Polished finish ensures cleanroom compatibility and precision contact.

Common Applications of Zirconia Polished Sheets :

- Semiconductor and Electronics: Substrates and insulators in microelectronic devices

- Medical Devices: Used in dental prosthetics, implants, and surgical tools

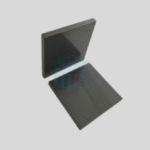

- High-Temperature Furnaces: As setters, spacers, and supports in kilns and sintering processes

- Optical Equipment: Stable and reflective mounts for lasers and lenses

- Chemical Analysis Labs: Sample holders and supports in harsh chemical environments

Conclusion

Zirconia polished sheets represent the pinnacle of ceramic material performance—delivering strength, durability, and polish that make them a preferred choice for critical applications. Whether you’re in R&D, production, or medical technology, zirconia sheets offer unmatched advantages in high-performance environments.