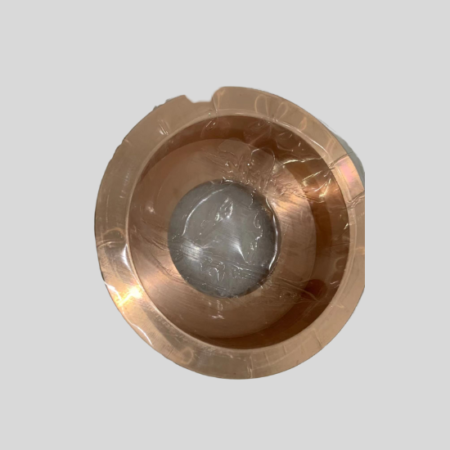

Nickel Alloy

Inquiry NowProduct Description

Nickel Alloys are high-performance metallic materials that incorporate nickel as the primary element, often combined with other elements such as iron, chromium, molybdenum, and copper. These alloys offer exceptional resistance to corrosion, high-temperature stability, superior mechanical strength, and excellent oxidation resistance. Due to their unique properties, Nickel Alloys are widely used in aerospace, chemical processing, marine, power generation, and medical industries.

At M-Kube, we can provide custom products made out of Nickle and its Alloy Products. Some of the possible ranges that we can offer includes:

Niobium Sheets/ Plates (Ni Sheets/ Plates):

~ Hot Rolling (4.1 to 50 mm) x (300 to 3000mm) x (500 to 4500mm)

~ Cold Rolling (0.3 to 4.0 mm) x (300 to 1000mm) x (500 to 4000mm)

Niobium Strips (Ni Strips): Thickness (0.015 to 1.2mm) x Width (3 to 150 mm) x L (> 600mm)

Nickle Rods (Ni Rods): Diameter (6 to 150 mm) x (500 to 6000 mm)

Nickle Pipes (Ni Pipes): Diameter (6 to 150 mm) x Wall thickness (0.8 to 8 mm)

Key Features

- Superior Corrosion Resistance – Performs well in harsh chemical and marine environments.

- High-Temperature Strength – Retains mechanical properties at elevated temperatures.

- Excellent Oxidation & Creep Resistance – Suitable for extreme industrial applications.

- Good Thermal & Electrical Conductivity – Efficient heat and electrical transfer capabilities.

- Superior Weldability, Ductility & Fabrication – Can be easily shaped, welded, and machined.

- Long Service Life – High durability ensures cost-effectiveness in demanding environments.

Technical Specifications

(Specifications may vary depending on alloy composition and application requirements.)

| Property | Value (Typical Range) |

|---|---|

| Composition | 30-80% Nickel with Iron, Chromium, Molybdenum, Copper, etc. |

| Density | 8.0 – 8.9 g/cm³ |

| Melting Point | 1,250 – 1,450°C |

| Tensile Strength | 500 – 1,200 MPa |

| Thermal Conductivity | 10 – 120 W/m·K |

| Electrical Conductivity | 1 – 40% IACS |

| Hardness | 100 – 300 HV |

| Oxidation Resistance | Excellent up to 1,200°C |

Applications

- Aerospace & Aviation – Used in jet engines, turbine blades, and exhaust systems.

- Chemical & Petrochemical Processing – Ideal for heat exchangers, reactors, and storage tanks.

- Marine & Shipbuilding – Resistant to seawater corrosion, making it suitable for propellers and hull components.

- Power Generation – Applied in nuclear, thermal, and renewable energy plants.

- Medical Industry – Used in implants, surgical instruments, and medical devices.

- Electronics & Telecommunications – Essential in high-performance electrical and thermal components.

Why Choose Nickel Alloy from Mkube?

- Premium-Grade Alloys – Manufactured to meet international quality standards.

- Customizable Compositions – Available in various grades and forms to suit diverse applications.

- Precision Engineering – Ensures superior mechanical and chemical properties.

- Corrosion & Heat Resistance – Designed for longevity in extreme environments.

- Expert Technical Support – Our team provides guidance in selecting the right alloy for your needs.

We, at M-Kube Enterprise, are an Australian company catering to:

– Premium quality laboratory equipment for analytical testing and sample preparation,

– Best in class laboratory consumables,

– Customized ceramic and refractory metal product solutions for high temperature applications and

– Top notch battery Equipment and battery consumables

We cater to various geographies like Australia, India, USA, Dubai, Indonesia, Malaysia, New Zealand, the Philippines, Singapore, South Korea, and Vietnam.

Our team of experts across different platforms can discuss and customize your requirements as per your needs. For more information, Please reach out to us on [email protected] or call us on +61478594746 to discuss your projects and we will be happy to explain the products in detail, tailor them to fit your requirements, and share detailed product catalogues.

We look forward to be one of your most trusted research partners.