Molybdenum Electrode

Inquiry NowProduct Description

General Information

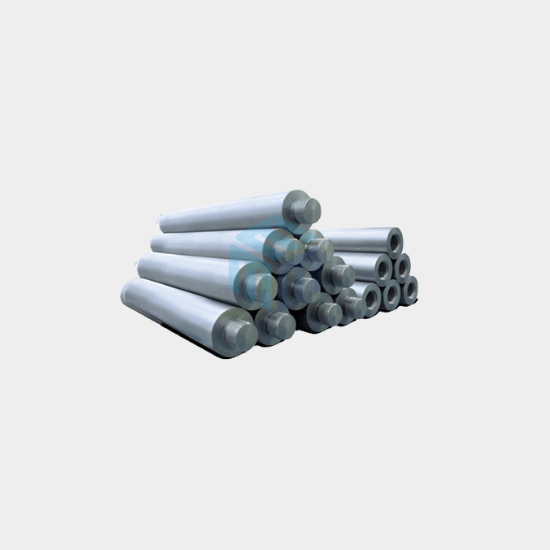

Molybdenum electrodes are produced by isostatic pressing i.e., by balanced pressing. It is made through powder metallurgy or sintering. Molybdenum can be formed into different shapes and types of electrodes. It is primarily used in the glass industry and rare earth industry as both these industries require electrodes that can bear extremely high temperatures. Molybdenum Electrodes are the appropriate product as it is strong enough to tolerate hostile glass melts and also possess great electrical conductivity.

It is not only designed to tolerate high temperatures and have great electrical conductivity, but also to save money and the environment. Usually, electrodes’ size vary between 30 mm to 70 mm in diameter and its length can reach up to 1500mm.

M-Kube Enterprise is an Australian company catering customized laboratory products, laboratory consumables, and laboratory solutions in Australia, Dubai, India, Indonesia, Malaysia, New Zealand, the Philippines, Singapore, South Korea, the USA, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us on info@mkube.com.au or call us on +61478594746 to discuss your projects.

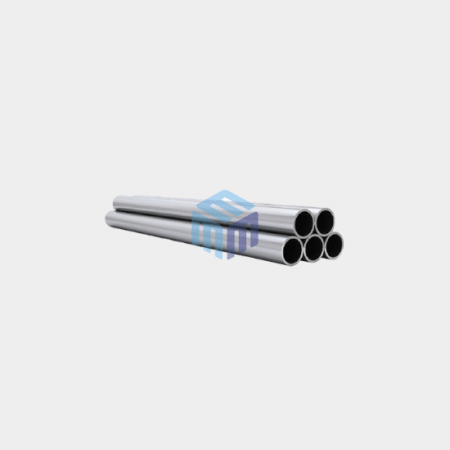

We also provide Molybdenum Wires, Molybdenum Crucibles, Molybdenum Mandrels, Molybdenum Foils, Molybdenum Sheets and Plates, Molybdenum Tubes, Molybdenum Rods, and Molybdenum substrates.

Key Features

Molybdenum is a refractory material that can withstand high temperatures, even higher than steel and nickel alloys. Due to its oxidation at low temperatures, it is best to use Molybdenum Crucibles in vacuum. Significant features include –

- High purity

- High creep resistance

- High dimensional stability

- Low co-efficient of thermal expansion

- Good thermal conductivity

- Good electrical conductivity

- Good stiffness, greater than that of steel

- High melting point (2622 °C)

- High boiling point (4639 °C)

- High red-hardness

- Good strength and ductility

- High density

Applications

Molybdenum Electrodes’ physical properties makes it the obvious choice to be majorly used in the glass industry to melt glass which further is used to make –

- Tableware and food containers

- Window glazing insulation

- Solar cells

- Electronic display panels

- Scientific apparatuses and containers

- Industrial vessels

Molybdenum Electrode are widely used in different industries such as:

- Heater Manufacturing

- Electrode Manufacturing

- Automotive

- Aerospace

- Metal Industry

- Metallurgy

- Stainless steel and Steel Industry

- Solar Cell

- Fuel Cell

- Energy Storage

- Nanotechnologies

- Electronic

- Glass Manufacturing Industry