Magnesia crucibles

Inquiry NowProduct Description

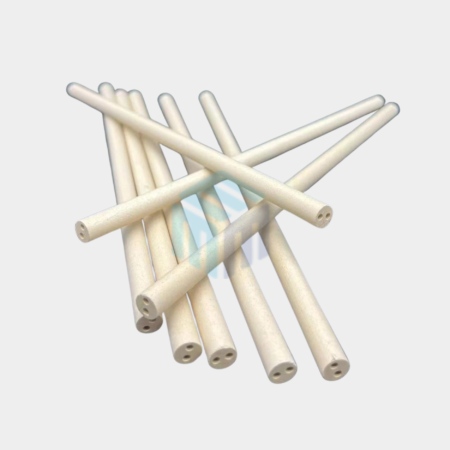

Magnesia Crucibles – High-Temperature MgO Ceramic Crucibles

Magnesia crucibles, made from high-purity magnesium oxide (MgO), are engineered for applications requiring resistance to extremely high temperatures and basic (alkaline) environments. With a melting point above 2800°C and an operating temperature of about 2000°C and strong chemical stability, they are ideal for materials testing, metal processing, and fusion analysis.

At M-Kube, we supply high-temperature magnesia crucibles in Australia for laboratories, metallurgy, ceramics, and research facilities. Our magnesia crucibles offer excellent performance in thermal processing where alumina or silica may not be suitable.

Custom and Standard Magnesia Crucibles for Extreme Heat Applications

We provide a variety of standard magnesia crucibles as well as custom-made sizes to meet unique furnace or experimental requirements. These crucibles are available in multiple shapes and wall thicknesses, with excellent structural integrity even at extreme temperatures.

MgO crucibles are available in various purity and different ranges from clay to yttria and alumina depending on the application. These high temperature resistance crucibles can work under different atmospheres with the stability at 24000C in air, 17000C in reducing atmospheres, 16000C in a vacuum, and 14000C in hydrogen.

Customisation options include:

- Cylindrical, conical, or tapered designs

- Custom heights, diameters, and wall thicknesses

- Open or closed-bottom configurations

- Polished or rough interior surfaces

- Batch or prototype production

As a reliable magnesia crucible supplier in Australia, we work closely with labs and manufacturers to ensure consistent performance, material compatibility, and short delivery times.

Take a look at some of our recently supplied Magnesia Crucibles. Whether you need a standard size or a custom solution, we’re here to help you find exactly what you need.

| S.No | Product Code | Description |

| 1 | MgO-CyC-030—050-3.5mm hole-00003 | 30 mm Diameter x 50 mm Height crucible with a 3.5 mm hole drilled at the bottom of the crucible |

| 2 | MgO-CyC-037—072-00007 | White Magnesia cylindrical crucible OD 37 mm, Height 72 mm |

| 3 | MgO-CyC-049-040.4-145-00006 | White Magnesia cylindrical crucible OD 49 mm, ID 40.4 mm, Height 145 mm |

| 4 | MgO-CyC-059-049-085-00005 | White Magnesia cylindrical crucible OD 59 mm, ID 49 mm, Height 85 mm |

| 5 | MgO-CyC-070—145-00004 | White Magnesia cylindrical crucible OD 70 mm, Height 145 mm |

| 6 | MgO-CyC-100-080-150-00001 | White Magnesia Cylindrical Crucible (Tall form) OD 100 mm, ID 80 mm, H 150 mm |

| 7 | MgO-CyC-170-140-050-00002 | White Magnesia Cylindrical Crucible (Flat form) OD 170 mm, ID 140 mm, H 50 mm |

| 8 | Custom sizes can be made available upon request.

Call us at +61-478-594-746 or email us at info@mkube.com.au for more information. |

Key Properties of MgO Crucibles – Thermal & Chemical Resistance

Magnesia crucibles are valued for their outstanding thermal and chemical performance under harsh process conditions:

- Extreme temperature resistance up to 2400°C and Operating temperature of about 2000°C

- Superior stability in basic and alkaline environments

- Low reactivity with metals and refractory materials

- High thermal conductivity and resistance to thermal shock

- Good electrical insulation properties at high temperatures

- Low porosity and high density

These properties make magnesia an ideal material for demanding analytical and high-temperature processes.

Applications of Magnesia Crucibles

Our MgO crucibles are widely used across various Australian industries and research institutes that deal with high-heat, corrosive, or alkaline conditions:

- Fusion flux analysis in mining and minerals labs

- Metallurgical sample preparation

- Rare earth and superalloy processing

- Thermal treatment of alkaline earth metals

- Crucible-based experiments in materials research

- Sintering and ash content testing

Also view our alumina crucibles, quartz crucibles and boron nitride crucibles to explore more options for thermal analysis and ceramic ware.

Work with Leading Magnesia Crucible Suppliers in Australia

M-Kube is a trusted partner for high-performance ceramic crucibles in Australia, offering tailored solutions for labs, testing facilities, and industrial plants. Our magnesia crucibles are tested for performance, purity, and durability.

We offer:

- High-purity MgO material grades

- Consistent product quality

- Custom dimensions and batch sizes

- Expert technical support

- Fast local service and delivery

Global-Standard Magnesia Crucibles with Local Australian Support

M-Kube supplies high purity magnesia crucibles to clients across Australia and internationally, supporting the most demanding thermal processes in mining, metallurgy, and R&D. Our products are built to global quality standards, backed by responsive customer service and technical support.

When your processes require reliability at extreme temperatures, trust M-Kube to deliver durable, high-purity MgO ceramic solutions.

Need magnesia crucibles for high-temperature or fusion applications in Australia?

Call us on +61478594746 or email info@mkube.com.au to discuss your requirements.

Our team is ready to assist with standard options or fully customised crucibles.