Boron Nitride Crucible

Inquiry NowProduct Description

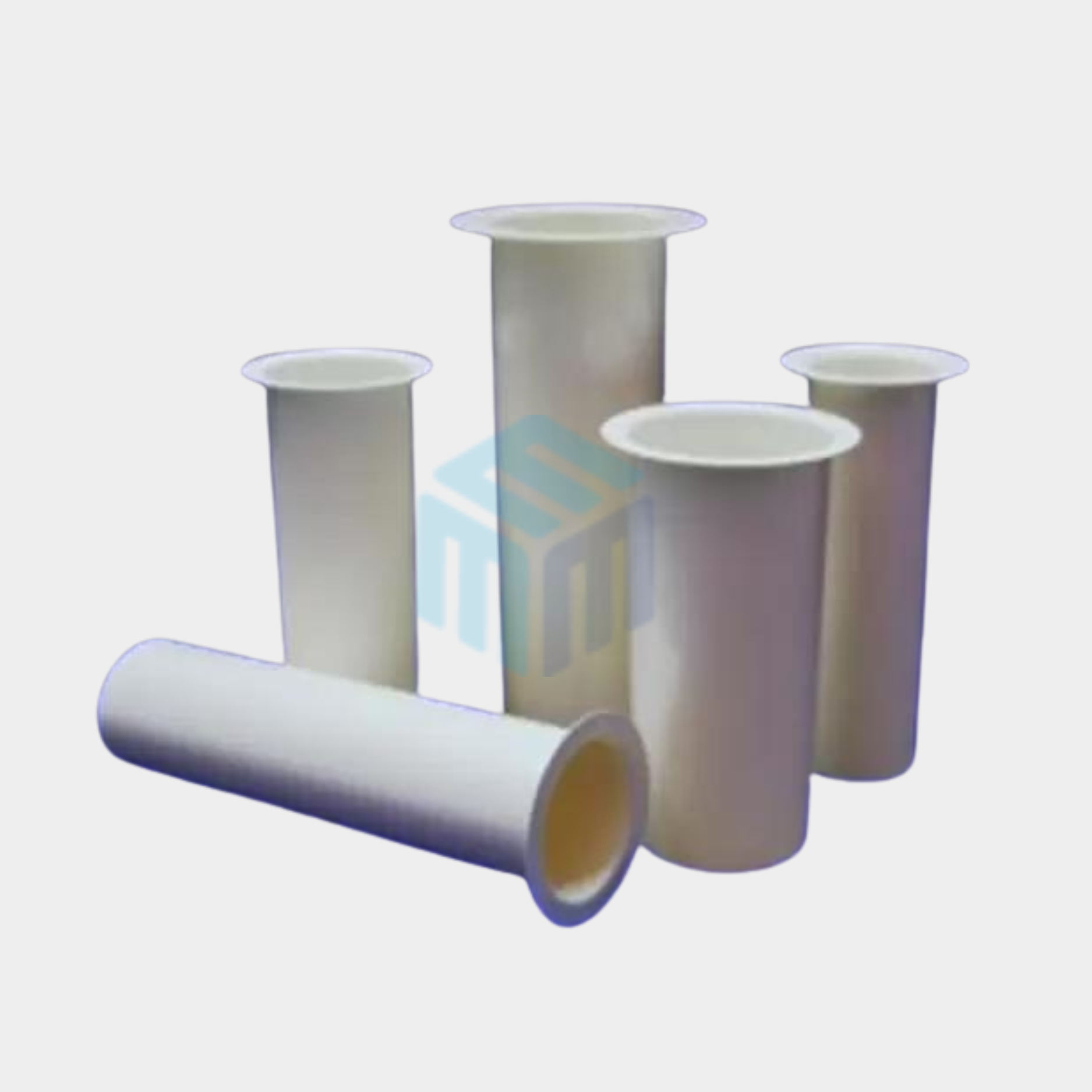

Boron Nitride Crucibles – High-Purity BN Ceramic Crucibles for Extreme Applications

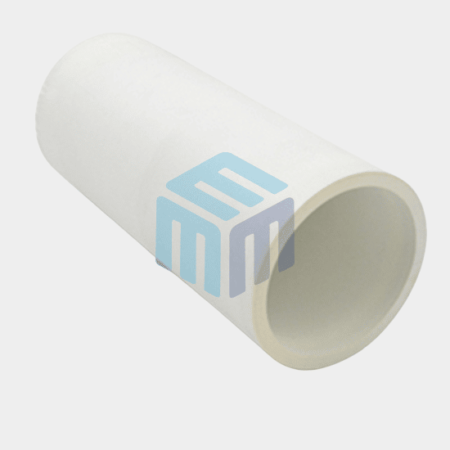

Boron nitride crucibles are high-performance ceramic components known for their unique combination of high thermal conductivity, electrical insulation, and non-wettability to molten metals. Made from hexagonal boron nitride (h-BN), these crucibles are ideal for use in vacuum systems, molten metal processing, and crystal growth applications.

Boron nitride is created artificially by reacting boric acid or boron oxide with nitrogen. It is present in different crystalline arrangements, two of the most common types being –

- hexagonal boron nitride (h-BN), similar to the structure of graphite

- cubic boron nitride (c-BN), similar to the structure of diamond

At M-Kube, we supply premium boron nitride crucibles in Australia, tailored for advanced material research, metallurgy, semiconductor, and aerospace sectors that demand superior thermal and chemical stability.

Custom and Standard BN Crucibles for Research and Industrial Use

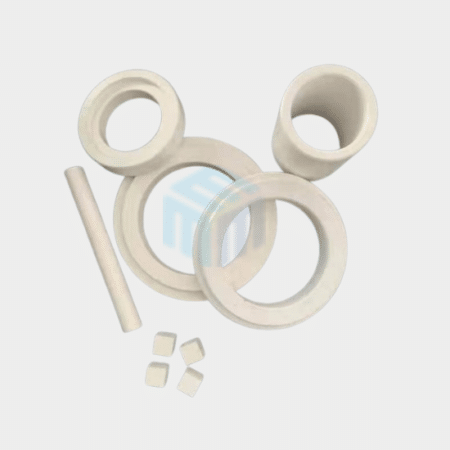

M-Kube offers both standard and custom BN crucibles to meet specialised industrial or research needs. Whether you require cylindrical, conical, or custom-shaped designs, our boron nitride crucibles are manufactured to deliver consistent performance under demanding conditions.

Customisation solutions include:

- Varied geometries: cylindrical, square, or tapered shapes

- Tailored wall thickness and capacities

- Polished or porous finishes depending on application

- Compatibility with vacuum, inert, or reducing atmospheres

- Precision machining for complex forms or assemblies

As a leading boron nitride crucible supplier in Australia, M-Kube ensures design flexibility, material integrity, and reliable delivery for both prototypes and production volumes.

Key Properties of Boron Nitride Crucibles

Boron nitride crucibles exhibit a rare combination of high thermal conductivity and electrical insulation, making them unique among ceramic materials:

- High Melting Point (29730C)

- Excellent thermal shock resistance

- Non-wettability to molten metals like aluminium, magnesium, and zinc

- High electrical resistivity even at elevated temperatures

- Lubricating surface for low friction and easy cleaning

- Chemically inert and corrosion-resistant

These features make BN crucibles ideal for sensitive thermal and chemical processes.

Applications of BN Crucibles in Vacuum, Metallurgy, and Electronics

Boron nitride crucibles are used across Australia in sectors requiring high-purity environments and resistance to metal adhesion or reactivity:

- Molten metal casting and containment (especially Al, Zn, and Mg)

- Crystal growth and optical material processing

- Vacuum evaporation and PVD coating systems

- Semiconductor and photovoltaic R&D

- Dielectric material studies in electronics

- Thermal analysis and sample prep in analytical labs

Explore other high-temperature ceramic options such as our Magnesia Crucibles and Alumina Crucibles designed for excellent thermal and chemical resistance.

Work with Leading Boron Nitride Crucible Suppliers in Australia

At M-Kube, we understand the precision required in high-tech and high-temperature applications. As a trusted boron nitride crucible supplier in Australia, we deliver consistent quality and tailored solutions backed by expert technical support.

Why choose M-Kube:

- High-purity, machinable boron nitride

- Reliable supply for R&D and production

- Custom shapes and sizes available

- Fast lead times and local support

- Commitment to quality and service

Global-Trusted BN Crucibles Backed by Local Australian Support

M-Kube supplies boron nitride crucibles to research institutes, aerospace firms, electronics manufacturers, and laboratories in Australia and internationally. We are proud to support clients working on advanced technologies with ceramics built to global performance standards.

Partner with us for BN ceramic crucibles that meet the most stringent thermal, chemical, and purity requirements — wherever you operate.

Looking for premium boron nitride crucibles in Australia?

Call us on +61478594746 or email info@mkube.com.au to discuss your project or custom requirements. We will help you find the ideal high-performance ceramic solution.