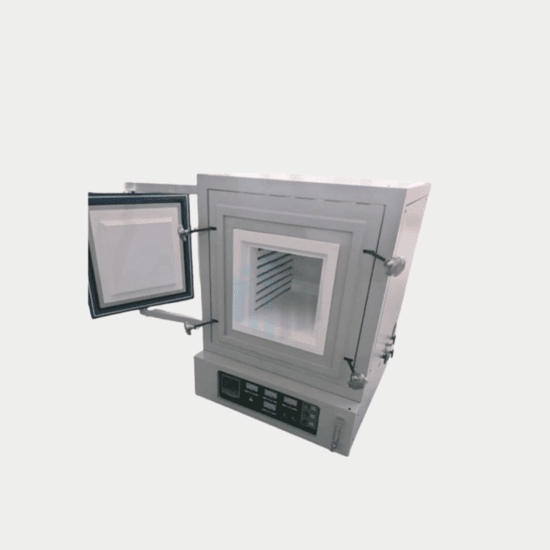

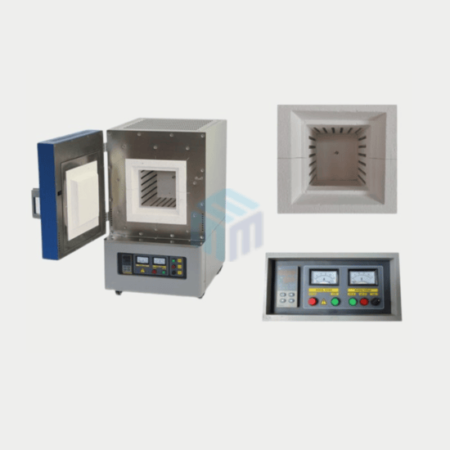

Atmosphere Furnace

Inquiry NowProduct Description

A laboratory atmosphere furnace is a specialized tool designed for precise thermal processing under controlled atmospheres, making it indispensable for high-quality material synthesis and analytical applications. This furnace allows users to create and maintain specific atmospheric conditions—such as inert, reducing, or oxidizing environments—within the chamber, which is crucial for processes like sintering, annealing, and thermal treatments of sensitive materials. With advanced temperature control and the ability to regulate various gas flows, the laboratory atmosphere furnace ensures consistent and reproducible results. Its robust design and safety features make it an essential instrument for research and development in materials science, chemistry, and other scientific disciplines where atmospheric conditions are critical.

| Atmosphere Furnace | ||

|---|---|---|

| Temperature | 1200°C, 1400°C, 1700°C, 1800°C | |

| Chamber Size | 1L(100*100*100mm), 4.5L(200*150*150), 12L(300*200*200mm) and 36L(400*300*300mm) | |

M-Kube Enterprise is an Australian company catering customized laboratory products, laboratory consumables and laboratory solutions in Australia, Dubai, India, Indonesia, Malaysia, New Zealand, Philippines, Singapore, South Korea, USA, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us on info@mkube.com.au or call us on +61478594746 to discuss your projects.

Frequently Asked Questions:

What are the differences between atmospheric and sealed furnaces?

Atmospheric Furnace:

- Operates in open air or simple gas flow.

- Suitable for general heating, ceramics, and metal treatments.

- More affordable and easier to maintain.

- Higher risk of oxidation and contamination.

Sealed Furnace:

- Fully enclosed with vacuum or inert gas environment.

- Ideal for oxidation-sensitive or high-purity materials.

- Offers better atmosphere control and uniformity.

- Typically more expensive and complex.

How does an atmospheric furnace work?

An atmospheric furnace operates by:

- Heating materials inside a chamber exposed to ambient air or a controlled atmosphere (e.g., nitrogen, oxygen, or hydrogen).

- Heating elements (like Kanthal or silicon carbide) transfer heat to the materials via conduction and convection.

- Often used for ceramics, glass, metal heat treatment, or sintering.

Some models allow gas flow control to reduce oxidation or modify material properties during the process.

What are some common issues with atmospheric furnaces?

- Oxidation of sensitive materials due to air exposure

- Contamination from open air particles

- Non-uniform heating in older models or poor insulation

- Scale formation on metals during high-temp exposure

- Limited atmosphere control, affecting material purity

Routine maintenance and using gas flushing can help reduce some of these issues.

Is there an atmospheric furnace supplier in Australia?

Yes. Atmospheric furnaces are available in Australia from various sources, including:

- M-Kube Enterprise – A global supplier that ships custom and standard atmospheric furnaces to laboratories and industries in Australia.

M-Kube Enterprise offers:

- Lab-scale and industrial models

- 1200°C, 1400°C, 1600°C atmospheric furnaces

- Custom sizes, programmable temperature profiles, and gas inlet options.

How do I maintain an atmospheric furnace for long-term performance?

To maintain an atmospheric furnace for long-term performance:

- Clean the chamber regularly – Remove debris, spills, and residues after each use to prevent contamination and damage.

- Inspect heating elements – Check for signs of wear, cracking, or uneven heating; replace if necessary.

- Monitor thermocouples – Calibrate or replace them to ensure accurate temperature control.

- Check insulation and seals – Examine the refractory lining and door gaskets for damage to avoid heat loss.

- Maintain gas lines (if applicable) – Inspect valves, connectors, and regulators if you’re using inert or reactive gases.

- Keep electronics in good condition – Check power cords, relays, and controllers regularly.

- Avoid overloading – Do not exceed recommended material volume or temperature ratings.

Follow the manufacturer’s maintenance schedule – Use approved spare parts and service procedures.

Regular maintenance enhances efficiency, safety, and furnace lifespan, and reduces unexpected downtime.

What safety features should I look for in an atmospheric furnace?

Look for over-temperature protection, door safety interlock, thermocouple failure detection, gas flow controls (if applicable), circuit breakers, emergency stop, programmable controller alarms, and a well-insulated exterior. These features ensure safe and reliable furnace operation.

Can an atmospheric furnace be upgraded to handle inert gases?

Yes, many atmospheric furnaces can be upgraded with gas inlet ports, flow controllers, and sealing improvements to handle inert gases like argon or nitrogen. However, full sealing and uniform gas flow may be limited compared to a true vacuum or sealed furnace. Always consult the manufacturer before modifying.