Atmosphere Furnace

Inquiry NowProduct Description

Atmosphere Furnaces – Controlled Thermal Environments for High-Precision Heat Treatment

M-Kube Enterprise supplies premium-grade atmosphere furnaces across Australia for industries and laboratories requiring precise temperature control under custom gas environments. Whether you’re performing sintering, annealing, brazing, or advanced heat treatment, our controlled atmosphere furnaces ensure consistent and contamination-free results.

From research labs to industrial manufacturing, we support clients who demand accuracy, repeatability, and thermal efficiency—making us a trusted atmosphere furnace supplier for Australian science and industry.

Controlled Atmosphere Furnace Range – Tailored for Heat Treatment and Materials Processing

Our furnaces are built to handle high-temperature processes in nitrogen, argon, hydrogen, vacuum, or custom gas mixtures.

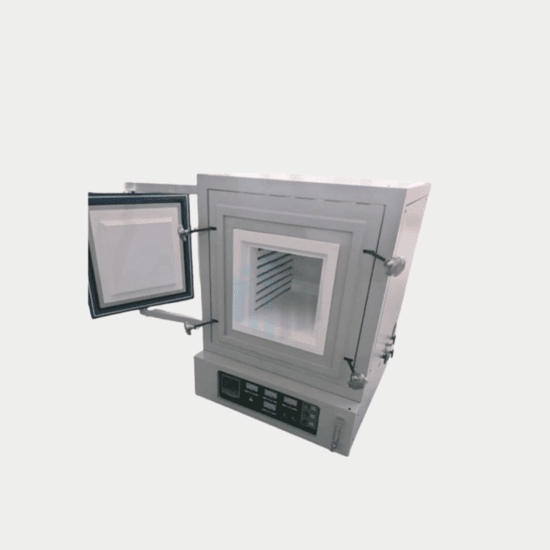

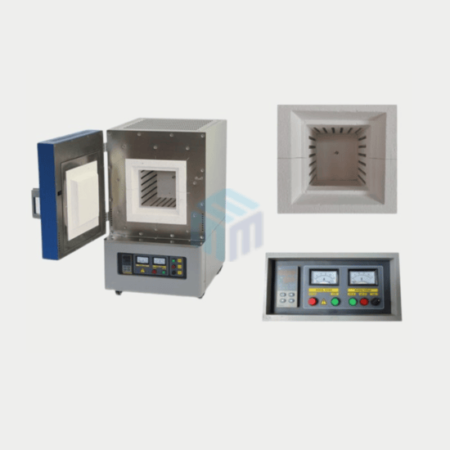

🔹 Controlled Atmosphere Muffle Furnace

- Temperature ranges from ambient to 1200°C to 1700 °C

- Chamber volumes from benchtop to pilot scale

- Fully sealed muffle chamber with inlet/outlet ports

- Ideal for materials R&D, ceramics, and catalyst testing

🔹 Controlled Atmosphere Heat Treatment Furnace

- High-temperature performance under reducing or inert gases

- Suitable for metal hardening, annealing, and alloy processing

- Programmable logic controller (PLC) with multi-segment ramp/soak profiles

Optional parts like Directly connected vacuum pump, touch screen, MoSi2/SiC heating elements, air systems can be made available, based on request.

Key Features of M-Kube Atmosphere Furnaces

- Stainless steel or quartz inner chambers

- Gas flow meters, pressure regulators, and purge systems

- Dual-layer insulation for energy efficiency

- Over-temperature protection and interlock systems

- Optional vacuum-purging capability and residual oxygen sensors

- Compatible with Argon, N₂, H₂, CO₂, and forming gas atmospheres

Whether you need a controlled atmosphere muffle furnace for your lab or a production-scale heat treatment furnace, we have the configuration to suit.

Applications of Atmosphere Furnaces

Our controlled atmosphere furnaces are used in:

- Metallurgical heat treatment and sintering

- Battery and electrode material processing

- Advanced ceramics and powder metallurgy

- Hydrogen-based annealing and brazing

- Semiconductor and aerospace component testing

- Research into oxidation/reduction reactions and phase transformations

We supply models suitable for both academic research and industrial scale-up.

Why Choose M-Kube Enterprise – Trusted Atmosphere Furnace Supplier in Australia

As a dependable atmosphere furnace supplier, M-Kube Enterprise provides:

- Customised furnace solutions to meet unique process requirements

- Local consultation and technical support

- Reliable delivery across Australia

- Integration support for lab and production environments

- Decades of combined experience in thermal system supply

Buy Controlled Atmosphere Furnaces in Australia – Engineered for Performance & Purity

M-Kube Enterprise supplies advanced atmosphere furnaces designed for performance and precision across Australian labs and manufacturing.

📞 Call +61-478-594-746

📧 Email info@mkube.com.au

to request a quote, technical spec sheet, or help selecting the right atmosphere furnace for your process.

Product FAQ's

Atmospheric Furnace:

- Operates in open air or simple gas flow.

- Suitable for general heating, ceramics, and metal treatments.

- More affordable and easier to maintain.

- Higher risk of oxidation and contamination.

Sealed Furnace:

- Fully enclosed with vacuum or inert gas environment.

- Ideal for oxidation-sensitive or high-purity materials.

- Offers better atmosphere control and uniformity.

- Typically more expensive and complex.

An atmospheric furnace operates by:

- Heating materials inside a chamber exposed to ambient air or a controlled atmosphere (e.g., nitrogen, oxygen, or hydrogen).

- Heating elements (like Kanthal or silicon carbide) transfer heat to the materials via conduction and convection.

- Often used for ceramics, glass, metal heat treatment, or sintering.

Some models allow gas flow control to reduce oxidation or modify material properties during the process.

- Oxidation of sensitive materials due to air exposure

- Contamination from open air particles

- Non-uniform heating in older models or poor insulation

- Scale formation on metals during high-temp exposure

- Limited atmosphere control, affecting material purity

Routine maintenance and using gas flushing can help reduce some of these issues.

Yes. Atmospheric furnaces are available in Australia from various sources, including:

- M-Kube Enterprise – A global supplier that ships custom and standard atmospheric furnaces to laboratories and industries in Australia.

M-Kube Enterprise offers:

- Lab-scale and industrial models

- 1200°C, 1400°C, 1600°C atmospheric furnaces

- Custom sizes, programmable temperature profiles, and gas inlet options.

To maintain an atmospheric furnace for long-term performance:

- Clean the chamber regularly – Remove debris, spills, and residues after each use to prevent contamination and damage.

- Inspect heating elements – Check for signs of wear, cracking, or uneven heating; replace if necessary.

- Monitor thermocouples – Calibrate or replace them to ensure accurate temperature control.

- Check insulation and seals – Examine the refractory lining and door gaskets for damage to avoid heat loss.

- Maintain gas lines (if applicable) – Inspect valves, connectors, and regulators if you’re using inert or reactive gases.

- Keep electronics in good condition – Check power cords, relays, and controllers regularly.

- Avoid overloading – Do not exceed recommended material volume or temperature ratings.

Follow the manufacturer’s maintenance schedule – Use approved spare parts and service procedures.

Regular maintenance enhances efficiency, safety, and furnace lifespan, and reduces unexpected downtime.

Look for over-temperature protection, door safety interlock, thermocouple failure detection, gas flow controls (if applicable), circuit breakers, emergency stop, programmable controller alarms, and a well-insulated exterior. These features ensure safe and reliable furnace operation.

Yes, many atmospheric furnaces can be upgraded with gas inlet ports, flow controllers, and sealing improvements to handle inert gases like argon or nitrogen. However, full sealing and uniform gas flow may be limited compared to a true vacuum or sealed furnace. Always consult the manufacturer before modifying.