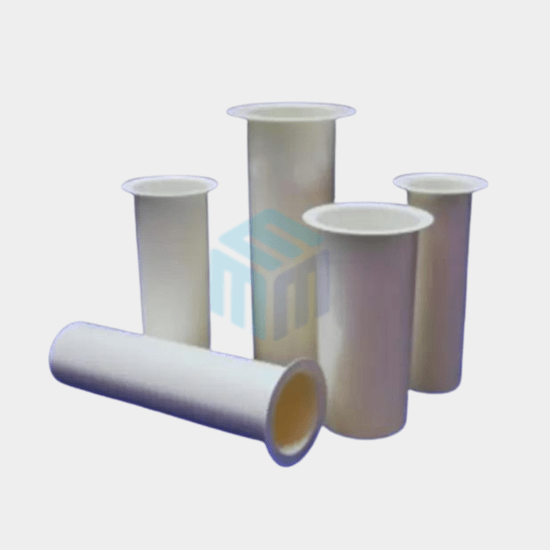

Boron nitride tubes and rods offer unique properties that make them valuable in high-temperature applications, especially in industries such as aerospace, electronics, and semiconductor manufacturing. Here are the key properties, uses, and maintenance tips for boron nitride tubes and rods:

Properties of Boron Nitride Tubes/Rods:

- High-Temperature Resistance: Boron nitride tubes and rods can withstand extremely high temperatures, typically up to around 1800°C (3272°F) in inert atmospheres and vacuum conditions. This makes them suitable for use in high-temperature furnaces, crucibles, and thermal insulation applications.

- Thermal Stability: Boron nitride exhibits excellent thermal stability, maintaining its structural integrity and dimensional stability at high temperatures without melting or softening. This property is crucial for thermal processing and heat management applications.

- Chemical Inertness: Boron nitride is chemically inert and resistant to most acids, alkalis, and corrosive substances. Boron nitride tubes and rods are therefore used in environments where chemical resistance and stability are essential, such as in semiconductor manufacturing and chemical processing.

- Electrical Insulation: Boron nitride is an excellent electrical insulator, making boron nitride tubes and rods suitable for electrical insulation in high-voltage equipment, plasma systems, and electrical insulation applications.

- Low Thermal Expansion: Boron nitride has a low coefficient of thermal expansion, meaning boron nitride tubes and rods experience minimal dimensional changes with temperature variations. This property helps prevent thermal stress-induced cracking.

- High Thermal Conductivity: Some forms of boron nitride, such as hexagonal boron nitride (h-BN), exhibit high thermal conductivity along the plane of the material. This property is beneficial for applications requiring efficient heat transfer and thermal management.

Uses of Boron Nitride Tubes/Rods:

- High-Temperature Furnaces: Boron nitride tubes and rods are used as heating elements, insulation components, and containment vessels in high-temperature furnaces for processes such as sintering, annealing, and heat treatment of metals, ceramics, and semiconductors.

- Semiconductor Manufacturing: Boron nitride is used in semiconductor manufacturing processes for components such as crucibles, boat liners, and wafer carriers. It provides thermal insulation, chemical inertness, and electrical insulation properties required in semiconductor fabrication.

- Thermal Management: Boron nitride tubes and rods are utilized in thermal management applications where high thermal conductivity combined with electrical insulation is needed. They are used as heat sinks, thermal interface materials, and insulating components in electronic devices and systems.

- Chemical Processing: Boron nitride tubes and rods find applications in chemical processing industries for handling corrosive chemicals, high temperatures, and reactive substances. They are used as reaction vessels, liners, and components in chemical reactors and processing equipment.

Maintenance Tips for Boron Nitride Tubes/Rods:

- Cleaning: Clean boron nitride tubes and rods regularly to remove residues, contaminants, and deposits that can affect their performance. Use mild cleaning agents and avoid abrasive materials that could scratch or damage the boron nitride surface.

- Avoid Mechanical Stress: Handle boron nitride tubes and rods with care to avoid mechanical stress or damage. Avoid dropping or impacting the tubes, especially at high temperatures.

- Inspect for Damage: Periodically inspect boron nitride tubes and rods for signs of wear, damage, or thermal stress. Replace any damaged components promptly to maintain performance and safety.

- Storage: Store boron nitride tubes and rods in a clean, dry environment to prevent contamination and moisture absorption. Use protective packaging or racks to avoid physical damage during storage.

By understanding the properties, uses, and maintenance tips for boron nitride tubes and rods, you can ensure their optimal performance and longevity in high-temperature, chemically challenging, and electrical insulation applications.

M-Kube Enterprise is an Australian company catering customized laboratory products, laboratory consumables, and laboratory solutions in Australia, New Zealand, Singapore, Malaysia, South Korea, India, Dubai, Philippines, Indonesia, and Vietnam.