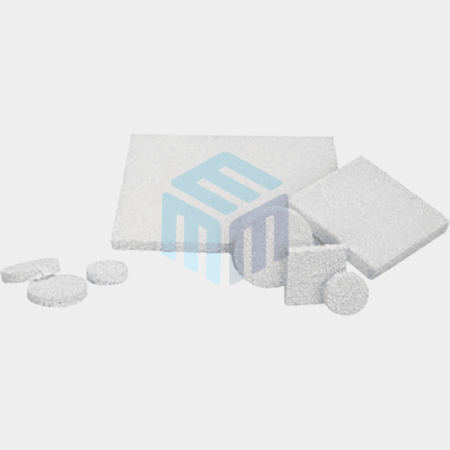

Highly Polished Alumina (Al2O3)Sheets

Inquiry NowProduct Description

Highly polished Alumina (Al₂O₃) sheets are advanced ceramic materials used in various high-performance applications due to their exceptional hardness, wear resistance, chemical stability, light weight and high-temperature resistance.

Manufacturing Techniques: Polished Alumina (Al₂O₃) Sheets –

- Sintering: Alumina powders are compacted and heated to temperatures below their melting point, facilitating particle bonding through diffusion. This process enhances mechanical strength and density.

- Polishing: Post-sintering, alumina surfaces are polished using ultra-fine alumina polishing powder or diamond paste to achieve a high-gloss finish.

Key Properties:

- High hardness and wear resistance

- Excellent thermal and electrical insulation

- Corrosion and chemical resistance

- High mechanical strength

- Biocompatibility (suitable for medical applications)

Tolerances and Surface Finish:

Achieving precise tolerances and superior surface finishes on materials like Alumina (Al₂O₃), Silicon Carbide (SiC), and Zirconia (ZrO₂) requires specialized machining and polishing services.

- Surface finish and polishing quality impact optical, electronic, and tribological properties.

- Brittle under extreme mechanical stress.

- Expensive compared to metals but provides longevity in harsh conditions.

The expected tolerances for highly polished Alumina (Al₂O₃) sheets depend on the manufacturing process, final application, and required surface finish.

Below are typical tolerance ranges for these materials:

Dimensional Tolerances

- General Precision (as-sintered): ±0.2 to ±0.5 mm

- Fine Precision (ground & polished): ±0.01 to ±0.05 mm

- Ultra-Precision (for optical and semiconductor applications): ±0.002 to ±0.005 mm

Surface Finish (Ra – Roughness Average)

- As-Sintered: Ra 1–3 μm

- Fine Ground: Ra 0.1–0.5 μm

- Polished (Mirror Finish): Ra 0.01–0.05 μm

- Ultra-Polished (Optical & Semiconductor Grade): Ra <0.005 μm (5 nm)

For example, silicon carbide and zirconia sheets used in semiconductor and optics applications often require Ra < 0.005 μm (mirror-polished surfaces).

Flatness

- Standard: 10–50 μm per 100 mm

- High-Precision Applications: 5 μm per 100 mm

- Optical and Semiconductor Applications: 1–2 μm per 100 mm

Flatness is critical for applications like wafer substrates, optical components, and high-precision mechanical parts.

Thickness Tolerance

- General: ±0.1 mm

- Precision-Machined: ±0.01–0.05 mm

- Ultra-Precision (e.g., semiconductor wafers, optical lenses): ±0.005 mm

Parallelism

- Standard: 50–100 μm

- Precision Applications: 10–20 μm

- Ultra-Precision Applications: <5 μm

Parallelism is essential for bearings, mechanical seals, and electronic substrates to ensure uniform thickness across the sheet.

Edge & Corner Tolerances

- Chamfered Edges (to prevent chipping): ±0.1 mm

- Sharp Edge Tolerance: ±0.05 mm

Silicon Carbide and Zirconia are brittle, so edge processing is often required to prevent chipping.

Applications:

Electronics & Semiconductor Industry:

Used as substrates, insulating plates, heat-resistant components and dielectric layers in microelectronics

- Substrates & Wafers: Used in microelectronics, IC packaging, and MEMS (Micro-Electro-Mechanical Systems).

- Heat Sinks & Insulating Layers: Polished Alumina and Polished SiC sheets are used in power electronics for heat dissipation.

- SiC Power Devices: Polished SiC sheets are used in MOSFETs, diodes, and transistors for high-power and high-frequency applications.

- Ceramic PCBs: Alumina and SiC substrates replace traditional FR4 or metal-core PCBs in high-performance electronics.

Medical & Dental:

Used in prosthetics, implants, precision surgical tools and medical devices due to biocompatibility.

- Dental Crowns & Implants: Zirconia sheets are used for their biocompatibility, strength, and aesthetic appeal.

- Prosthetics & Joint Replacements: Alumina and zirconia components in hip and knee implants.

- Surgical Tools & Equipment: Highly wear-resistant and sterilization-friendly ceramic components.

Aerospace & Defense:

Thermal barriers and wear-resistant components in high-stress environments like engine parts, heat shields, and structural components.

- Thermal Barrier Coatings (TBCs): Zirconia sheets are used as insulation layers in jet engines and rocket nozzles.

- High-Temperature Components: SiC and alumina parts are used in heat shields, nose cones, and missile systems.

- Optical Components: Precision polished SiC mirrors and lenses for satellites and high-precision optical instruments.

- Armor & Ballistics: SiC and alumina sheets are used in body armor and vehicle armor due to their light weight, high hardness and impact resistance.

Industrial & Laboratory Equipment:

Used in high temperature furnaces, crucibles, and as wear-resistant liners.

- Cutting Tools & Grinding Media: SiC and zirconia are used in high-performance cutting tools and abrasives.

- Mechanical Seals & Bearings: Alumina and SiC sheets are used in pumps, compressors, and high-wear applications.

- High-Temperature Furnaces & Crucibles: Used in metallurgy, ceramics, and materials research.

- Chemical Processing Equipment: Corrosion-resistant ceramic sheets for tanks, piping, and reactors.

Energy & Nuclear:

For high-temperature reactor components and insulators.

- Nuclear Reactor Components: SiC and zirconia are used as radiation-resistant materials in fuel cladding.

- Hydrogen Fuel Cells: Alumina sheets are used as insulating and structural components.

- Solar Power & Concentrated Solar Systems: SiC and alumina sheets are used in high-temperature solar receivers.

Automotive & Electric Vehicles (EVs)

- SiC Power Modules: Used in EV inverters and fast-charging systems to improve efficiency and reduce power loss.

- High-Performance Brake Discs: SiC-reinforced ceramic brake discs offer superior wear resistance and heat dissipation.

- Sensors & Actuators: Alumina and zirconia-based components in fuel injection systems and exhaust sensors.

- Battery heat shields & insulators: Alumina sheets for thermal protection in EV batteries.

Optics & Photonics Industry

- Precision Mirrors & Lenses: SiC and alumina sheets used in high-performance optics.

- Laser Components & Windows: Used in high-energy laser systems for military and industrial applications.

- Astronomical Telescopes: SiC mirrors are used in space telescopes and observatories.

Why Choose M-Kube Polished Alumina Sheets?

We, at M-Kube, believe in providing Differentiating Value-Added Services like:

- Custom machining & polishing: Provide finished, ready-to-use ceramic components.

- Technical consulting: Help customers select the right ceramic materials.

- On-demand prototyping: Support R&D teams with fast-turnaround ceramic parts.

At M-Kube, we offer comprehensive rough and finish grinding on various ceramic materials, by specializing in precision grinding, lapping, polishing, machining and laser cutting of these ceramic components. Our capabilities encompass surface grinding, centerless grinding, OD/ID grinding, honing, lapping, and polishing. We also maintain top notch in-house testing facilities to ensure the quality and performance of these products

We strongly recommend you to consult M-Kube team and discuss your specific requirements, including material type, desired tolerances, surface finish, and application, to ensure that we at M-Kube, can meet your exact specifications.

We, at M-Kube Enterprise, are an Australian company catering to:

- Premium quality laboratory equipment for analytical testing and sample preparation,

- Best in class laboratory consumables,

- Customized ceramic and refractory metal product solutions for high temperature applications and

- Top notch battery Equipment and battery consumables

We cater to various geographies like Australia, India, USA, Dubai, Indonesia, Malaysia, New Zealand, the Philippines, Singapore, South Korea, and Vietnam.

Our team of experts across different platforms can discuss and customize your requirements as per your needs. For more information, please reach out to us on +61-478-594-746 and we will be happy to explain the products in detail, tailor them to fit your requirements, and share detailed product catalogues.

We look forward to be one of your most trusted research and vendor partners.