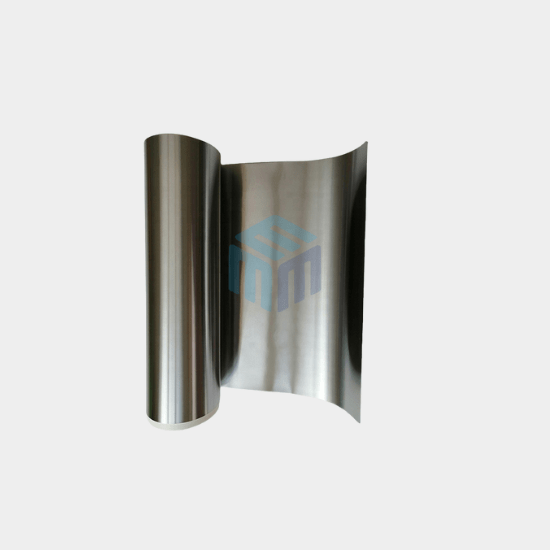

Tungsten Foil

Inquiry NowProduct Description

General information

Tungsten foils are developed from tungsten bars that are manufactured by sintering. Tungsten bars are rolled and pressed with extreme pressure compressing and tightening the particles. This process produces tungsten foil that is slightly more fragile than the bars and can bend under its own weight. Tungsten foils are 0.001 inch thick, but the width is determined on the requirement. Tungsten foils are then shipped as coils or sheets. Different kinds of surface conditions are available such as glossy, and matte. Generally, the surface is similar to that of steel, uniform and glossy.

Tungsten is one of the toughest and most durable metals in its purest form therefore it is usually mixed with other metals to form strong, high heat resistant alloys. Because of its beneficial properties it is also used in a variety of industries.

M-Kube Enterprise is an Australian company catering customized laboratory products, laboratory consumables, and laboratory solutions in Australia, Dubai, India, Indonesia, Malaysia, New Zealand, the Philippines, Singapore, South Korea, the USA, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us on [email protected] or call us on +61 478901616 to discuss your projects.

We also provide Tungsten Crucibles, Tungsten Boats, Tungsten Electrodes, Tungsten Mandrels, Tungsten Wires, Tungsten Sheets and Plates, Tungsten Tubes, Tungsten Rods and Bars, and Tungsten substrates.

Key properties

- High melting point (3410 °C)

- Low thermal expansion

- High electrical resistance

- Low vapour pressure

- High density

- Resistance to oxidation and creep

- Extreme hardness

- High tensile strength

Application

Tungsten foil has high heat resistance, ductility and low thermal expansion, so it is used: –

- As a heat exchanger heating element in chemical processing

- In capacitors, chemical anti-corrosion and textile equipment (this doesn’t sound right. Please verify)

- As target materials for optical & semiconductor industries

- In construction industries

- In engineering industries

- In medical industries